Play With Diamonds Gold Jewelry Manufacturer

Strong R&D Department

Play with Diamonds puts research and development at the heart of our operations to maintain our position as a leading gold jewelry manufacturer in Thailand. Our R&D department includes skilled and innovative employees whose sole job is to look for ways to improve our current manufacturing practices, and where possible, replace them with better alternatives. After all, change is inevitable, and those who can’t keep up will always remain behind.

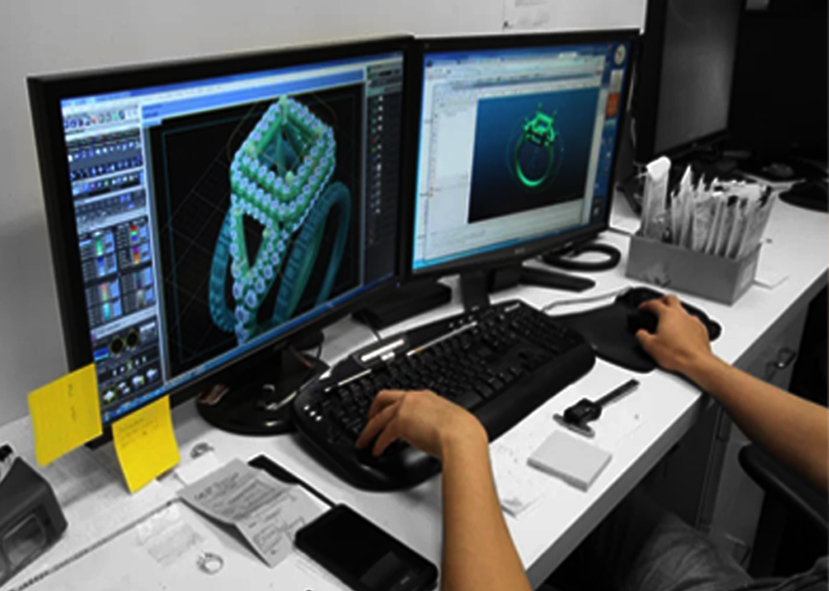

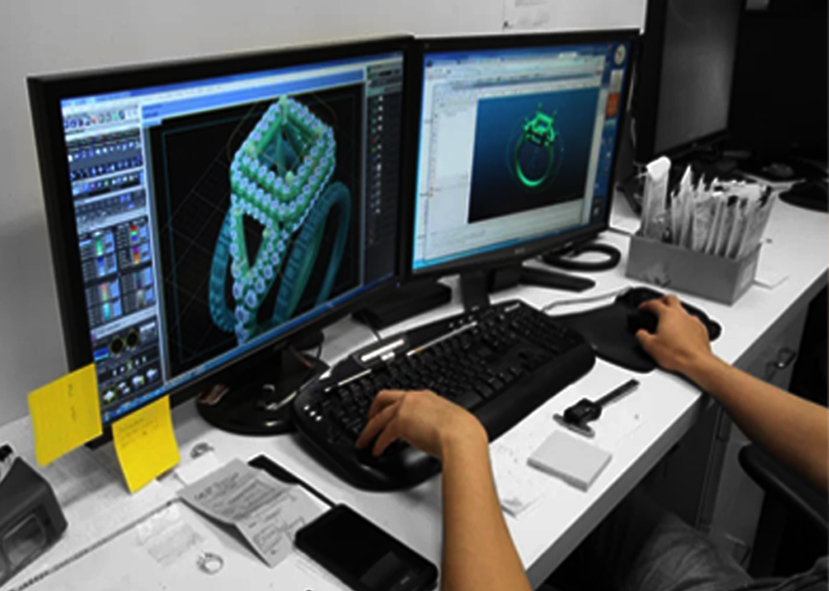

Talented jewelry designers and 3D modeling artists

If you want us to design custom gold jewelry for you, you’ll be glad to know that we employ the best jewelry designers available to us. Our designers work with equally talented 3D modeling artists to take your desired jewelry concepts one step closer to actualization.

3D printing machines

After our 3D artists use the designer’s jewelry sketches to make 3D models, the next step is to create wax molds straight from 3D software to be ready for casting. Our 3D printing machines are up to date and utilize premium 3D software like CAD, Matrix, and Rhino to ensure excellent results.

We use top-of-the-line casting machinery

Once the wax molds are ready, the next step is to cast the gold. This process requires nanometer-scale precision, which is impossible to accomplish by hand or average casting equipment. The trick here is to make sure that the liquid gold is spread out evenly throughout the mold. Thus, we have invested in cutting-edge casting machinery that utilizes proven top-of-the-line techniques for incredible precision.

We strive to capture every line, groove, and artistic expression just as you dreamed it.

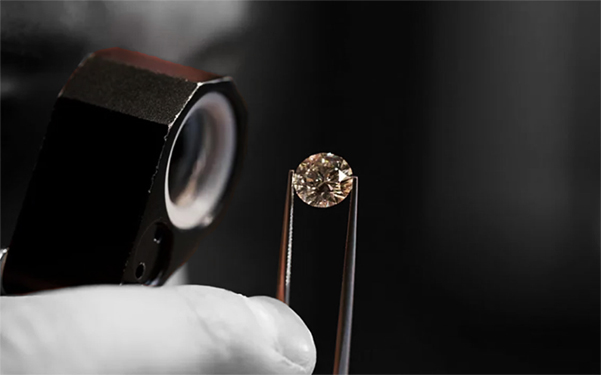

Micro setting and wax setting Gemstones

We have all types of gemstones available to crown your gold jewelry. Our well-trained personnel are skilled in all settings, allowing us to provide traditional, micro, and even the most advanced wax settings to our clients.

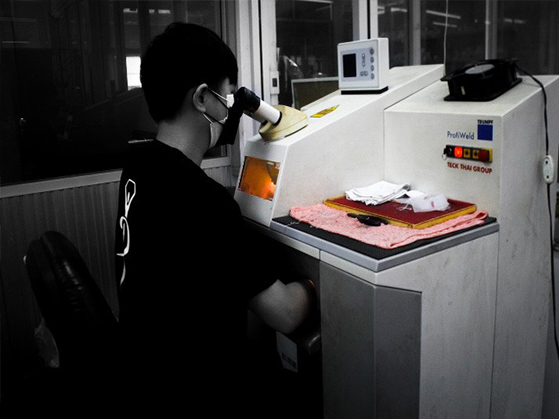

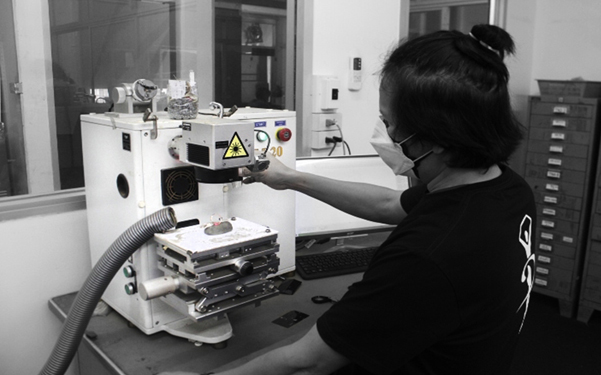

Laser welding machines

We use laser welding machines to connect hoops, solder, and perform other finishing touches during the last production stage. The precision of laser welding allows our Bangkok jewelry factory to reach higher quality.

Filling and polishing

After casting, the following steps involve filing and polishing the jewelry, which is done by the delicate hands of highly skilled and experienced artisans. Our craftsmen and women have the talent, precision, and incredible attention to detail needed to perform filing and polishing to pass the high standards of QC.

Laser engraving

Next, we use a laser engraving machine to engrave the gold grade (10k-417/ 14k-585/ 18k-750) before adding the customer’s hallmark. Our engraving method is as precise and clear as you would expect from a leading Bangkok jewelry factory.

Quality Control

Being a quality-focused wholesale gold jewelry manufacturer, we ensure that the gold jewelry meets the client’s desired criteria. Therefore, we always put the jewelry through rigorous quality control procedures. Our experienced QC department can handle a high capacity of goods professionally, so you can be sure that every jewelry piece you receive has been tailored to specification.

We have over 15 years of experience in jewelry making. Contact us today and see how we can help your jewelry business grow.